Shrimps are among the most popular seafood items and because of the resulting demand of shrimp in the US, Asia and Europe, the global trade volume of farmed shrimp has increased to a total production volume of 3,95 Mio tons.

This is an increase of 400% from the beginning of farming in the 60s until today.One distinguishes between warm and cold-water shrimp as well as salt and fresh watershrimp. The family of shrimp comprises over 3000 species. However, only a handful can be produced under aquaculture conditions. The so called Western White Shrimp or White Tiger Shrimp (lat. Litopenaeus vannamei) has the highest share of all farmed shrimp worldwide.

Until now White Tiger are farmed in one of the 50.000 farms that cover a total area of 1.2 Mio hectares in the main production areas in Latin America and Asia.The rapid increase in the production in the coastal shrimp ponds with low water exchange, high water temperatures and high stocking densities resulted in substantial issues: the fast spread of epidemic bacterial and viral diseases caused high losses that often were treated by incorrect use of non-licensed products leaving residues in the shrimp.

The extensive clearance of mangrove forests to build more ponds in the growth phases in the 90s were heavily criticized by environmental organizations. All that has led to a critical view on these products in many countries and to a search for more alternative, sustainable methods for the production of a biosecure and high-quality seafood product.

The founder of FutureFish Aquaculture had the vision to find a sustainable approach to the production of shrimp in the North of Europe despite of the climatic conditions that are not in favor to grow tropical aquatic species. These shrimps could be marketed without long-distances transports and fresh on ice as an alternative to all the frozen products of unknown quality history.

The first experimental recirculation system for shrimp was developed, built and run by Gerrit Quantz in an isolated greenhouse at MariFarm in Kiel/Strande, Germany in 2000. In 2004 a pilot-scale shrimp RAS tank was put into operation and the farmed shrimp were marketed successfully to high-end gourmet restaurants.

As the favorite species, the so called Western White Shrimp or White Tiger Shrimp was chosen because of the following reasons:

• Postlarvae for stocking can be ordered from commercial hatcheries all season

• Certified healthy populations are assured (SPF = “Specific PathogenFree”)

• Shipping the juvenile shrimp is relatively easy with little losses.

• The shrimp can reach a mean weight of 30g after less than 6 months

• Varying salinities are accepted, even a farming in fresh wateris possible

The FutureFish Aquaculture Shrimp farming RAS technology was developed to consider the special needs of the shrimp. Although the stocking rates and the feed input for a shrimp farm are considerably lower than it is intensive fish farms we base our farm systems on a RAS technology proven for fish farms, representing the state-of-the-art in water recirculation treatment.

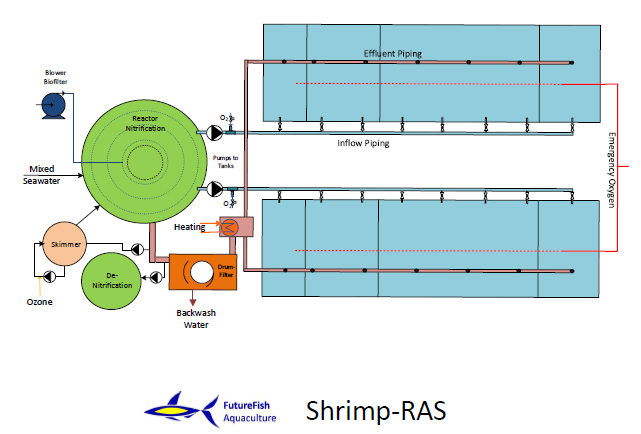

The shrimp grow in rectangular “raceways” of up to 40 m length. We developed an optimized stocking/harvesting scheme that is based on a flexible partitioning of the tanks into 3 compartments of different sizes. Every 2nd month all cohorts in the compartments are transferred stress less into the next, bigger section and a new group of post-larvae (=PLs) is introduced into the first compartment. After 3 transfers and a growth time of 6 month the shrimp from the last compartment can be harvested.

The tank water flows by gravity into a drum filter for mechanical removal of solids. The fine nylon-mesh of the filter is back-washed automatically to remove the trapped feces and other solids.

The tank water effluent is not only transporting solids but is also loaded with ammonia, a toxic product of the shrimp metabolism. To keep the ammonia concentrations below critical concentrations the water is treated in a bioreactor. The degradation (nitrification) of ammonia through nitrite to the less harmful nitrate is done by specialized strains of bacteria. To keep these microorganisms in the reactor tank we offer them specially designed, floating PE-biocarrier with a high specific surface to settle on.

To avoid an accumulation of the nitrate as the end product of the nitrification we add a further biological treatment step with a specially designed denitrification reactor. In this reactor heterotrophic bacteria are reducing the nitrate in an anaerobic environment to nitrogen gas that is removed from the system.

In a side loop water is treated in a protein skimmer for removal of fine particles and bacteria. At the same time the water is enriched with ozone gas, an effective reducing agent for the break-up of organic molecules. Before pumped back to the shrimp tank technical oxygen is added for optimal concentrations in the tank water.

All pumps, electrical units, water flows and levels and the important water parameters are monitored by numerous sensors and controlled by industrial, PLC-based automation. If any disturbances or deviations from the predetermined data occur, staff will immediately be notified.

The FutureFish Aquaculture shrimp farms are modular with a standard yearly output of 7.5 tons of he-on shrimps per unit. Each module consists of two raceways that can be constructed as a 2 – tier rack system or on ground floor. Each two tanks are connected to a self-sufficient RAS unit.

For further information such as the basic requirements for a shrimp farm in terms of heat, water and electrical supply and the footprints for the building, ask for the Shrimp Information Brochure